All projects should have a clearly defined scope of work, budget, and scheduled completion date. However, should any changes be introduced to the project, their timing (and scale) will determine the potential impact on these and various other variables, and on the project overall.

The effects of early changes may be easier to mitigate than later ones. Generally, the later a change occurs, the greater its potential cost and schedule impact – and risk of a dispute arising. This is often referred to as the project “growing a tail”.

HKA’s Fifth Annual CRUX Insight Report – Battling the Headwinds presented a regional analysis of claims and dispute causation worldwide. Not for the first time, this identified change in scope as the top-ranking cause of claims and disputes, followed by design conflicts. These arose out of late, inaccurate and/or incomplete design information.

Domino effects

Change can often have a domino effect. In construction delay analysis, we can see how the impact of one delay event cascades, affecting subsequent activities, resulting in a chain reaction (or causation) of delays throughout a project. The delay in one activity or task affects the start or completion of dependent subsequent activities, so that delays ripple through the project schedule. This impact can also extend beyond a single project, even causing complications across an entire capital projects programme.

To cite a hypothetical shipbuilding example, the dry dock or slipway in a shipyard is a bottleneck in the shipbuilding process. This is a constraint that always falls on the critical path of any new-build vessel. If the dry dock is only big enough for one ship, it’s obvious that a second ship cannot have its keel laid until the first ship is floated out of the dock.

“HKA’s Fifth Annual CRUX Insight Report – Battling the Headwinds […] identified change in scope as the top-ranking cause of claims and disputes, followed by design conflicts.”

The domino effect can be defined as the cumulative impact produced when one event sets off a chain of similar events. This is not uncommon in complex construction projects such as petrochemical plants, offshore oil and gas production facilities, and any other projects where intricate piping and electrical disciplines form a major part of the installation and are often the critical path activities towards the end of the project.

Skyline charts

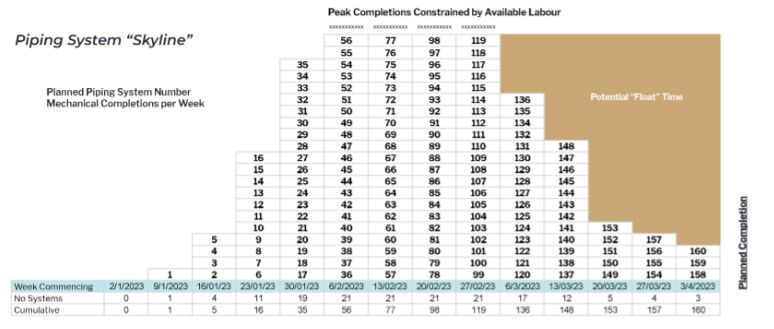

In such circumstances traditional Gantt chart planning is often superseded by a more detailed level of planning using run-down graphs or, as I have seen several times on offshore projects, ‘skyline’ charts or schedules. These skylines are spreadsheets that identify on a week-by-week basis when, for example, each piping system is scheduled to be mechanically complete. The system identifier is entered into a cell on the spreadsheet against the planned completion date as shown in Figure 1.

Figure 1 – Baseline Skyline Schedule

This spreadsheet shows that the maximum number of systems per week which can be expected to be completed is 21. In this case, the relevant constraint is the amount of available labour. Other constraints, such as access to work areas or the supply of specialist equipment, may also need to be considered.

The brown highlighted area is the ‘float’ where any delayed earlier systems can, domino-like, be toppled – or to put it another way, stacked – for completion, until such time as all the float capacity is used up. This confirms the fact that not every delay to a system is necessarily a critical delay that risks late completion. However, as earlier systems are delayed, the float is reduced. This makes the risk of a delay to overall completion increase.

Progress updates

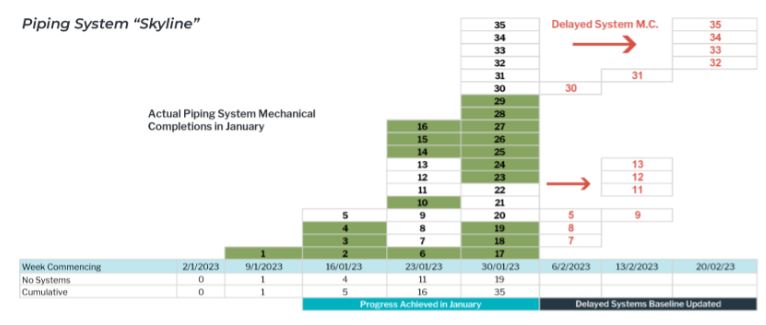

When a progress update is done (preferably on a weekly basis), it will show the systems that have been completed and those that have not. Given there is usually a limited amount of flexibility in the order in which piping and electrical systems need to be completed, any delay to an early system will mean that a later system has to be moved back in the skyline to make way for the delayed early system to be completed first. This progress is graphically represented on the updated skyline shown in Figure 2.

Figure 2 – Progress Updated Skyline

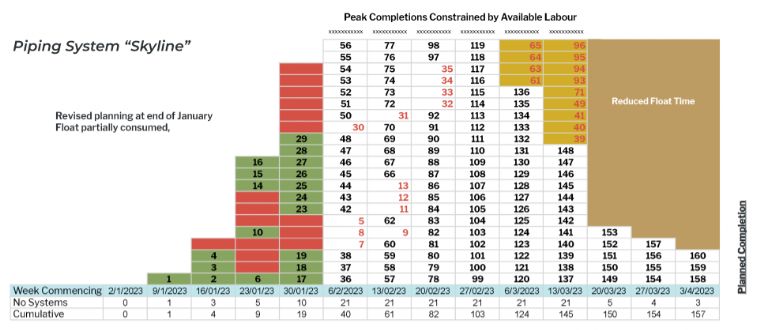

The completed piping or electrical systems are shown in green, whereas the delayed piping systems are left white and the system number is reassigned to a new planned completion date in the skyline. As other systems have to make way, the revised planned skyline to completion in Figure 3 shows these, after they are moved to their new location in the area of float, highlighted in orange.

“The large Gantt charts produced by modern software can be just too difficult to understand in some situations, and off-putting to tribunals.”

Figure 3 – Revised Skyline to Completion

Warning notices

This weekly progress updating may well continue to demonstrate the domino effect of any earlier design changes, increases in the scope of work, acts of prevention or culpable delay by the contractor. Whenever this situation occurs and the orange cells appear, it may well be time to issue an early warning notice under the terms of the contract, albeit an overall delay to completion may not yet be inevitable. The reduced float does, however, increase the risk of just such a result.

As weekly progress reporting continues, and if all the float is consumed, then a delay notice must be issued in order to maintain any potential entitlement to an extension of time, should the cause justify such an outcome.

This process of updating the skylines on a weekly basis is also helpful in identifying the causes of disruption to the works and will assist in the quantification of any losses arising.

Tribunal evidence

Having used this approach in a recent arbitration where the client achieved an award in its favour, I found the simplicity of the skyline presentation was well received by the tribunal. The large Gantt charts produced by modern software can be just too difficult to understand in some situations, and off-putting to tribunals.

In this case, the skyline approach successfully demonstrated that though delays to the piping installations occurred, they were not the cause of the critical delay to Sailaway. That was due to a significant change order that increased the number of sea fastenings (i.e., steel grillages fixing the platform to the transportation vessel). Transportation of the platform could not commence until this additional work – involving some 150,000 man-hours – was completed. This point was confirmed by adducing the appropriate factual evidence from the project team; causation (like delay) is a factual matter, not a matter of opinion.

Of course, there are several other ways this level of planning can be carried out. However, the skyline method clearly found favour with that tribunal, and may well prove useful again depending on the circumstances of a case.

A valuable tool

A delay in one activity or event on a project will often have a direct impact on subsequent tasks, causing a chain reaction of delays. Recognising and analysing these interdependencies is crucial in construction delay analysis so we can accurately assess the causes and effects of delays, allocate responsibilities, and develop strategies to mitigate the domino effect and minimise overall project delays.

If a dispute arises in the event of a delay, then tools such as the skyline chart become invaluable in determining a fair and robust argument to reach a resolution. It is, therefore, essential to keep these records up to date if experts are to be able to use this type of analysis effectively.